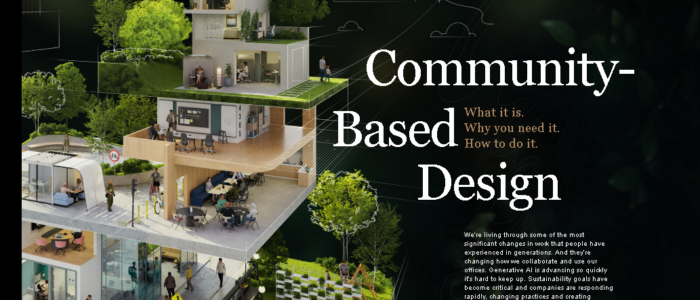

The future of office workspace will rely on community-based design according to Steelcase

Steelcase explores designing offices like thriving communities as the solution to meeting the challenges of the evolution of work:

“The parallels between neighborhoods and offices are striking. Who, after all, has a direct interest in creating diverse, vital spaces that foster creativity and serendipity? Employers do.”

– Malcolm Gladwell, Designs for Working, The New Yorker, December 2000

The article makes a number of good points highlighting the need for both private and shared workspaces that foster focus and engagement, much like thoughtfully designed communities. It emphasizes flexible, people-centered layouts that support various work styles and help employees feel connected and productive.

Once you’ve envisioned how you want your workspace to look and feel, we’ll be happy to assist in global shipping and installation of all the necessary equipment and furnishings. In fact, that’s our specialty.

Read more about the concept of community-based office design at the following link: “Community-Based Design: What it is. Why you need it. How to do it.”

Critics Of Open Plan Offices Shift Their Focus To The Downside Of Virtual Meetings

Why can’t remote work replace the physical workplace altogether? According to an article in the Harvard Business Review cited by workplaceinsight.com,

“…Meetings are important, of course, but not more so than human moments, because it is relationships, not merely acts of collaboration, that create trust between coworkers. Studies have long shown that frequent in-person interactions lead to commitment, support, and cooperation among people on teams. That’s why many tech companies that boast about being 100% online still have an office. Even those that have no physical space emphasize that teams should meet face-to-face on a regular basis…”

Read more at:

https://workplaceinsight.net/well-at-least-nobody-is-whinging-about-open-plan-offices-anymore/

Paris Trading Floor Project Completed Despite Lockdown And Riots

Trading desks manufactured by LaCour were shipped from New Jersey to Paris, France and installed without a hitch in the midst of the pandemic lockdown. The project was completed minutes before riots broke out in the streets of Paris to protest the lockdown. The shipment was routed via the port of Rotterdam, Holland to bypass delays at the port of LeHavre, France. The Dutch installation crew were equipped with parking permits from French Police and special dispensations allowing them to work until 6 pm every day, at which time they had to return to a rented apartment to comply with the evening curfew.

Alibaba And Amazon Battle For 3PL Supremacy

Alibaba and Amazon are battling to control the third party logistics market by providing supply chain logistics services to outside clients.

Cainiao, the logistics division of Alibaba, is now offering end-to-end logistics services to Japanese and South Korean importers and exporters and have started an air charter service between Asia and South America. While Amazon is well on its way to becoming a global player in providing logistics services to other companies as an extension of the logistics infrastructure they created to serve their own needs, Alibaba understands they must catch up with Amazon’s growing dominance in the field to remain viable.

Cainiao aims to cover international shipping by sea and air, customs clearance, trucking, warehousing and last mile delivery. By offering an in-house turnkey service, they will reduce transit times, take control of their supply chain and reduce costs that will benefit consumers through more competitive pricing and faster delivery times.

Alibaba plans to operate about 1,300 chartered flights by the end of 2020. Amazon is offering a full range of logistics services in Europe and recently opened an air hub in Germany to support its Prime delivery service . In the U.S., Amazon offers ocean freight services for its own imports as well as other customers.

Read more about this transformation at:

https://www.freightwaves.com/news/alibaba-moves-into-japan-with-third-party-logistics-offering

(Photo credit: Alibaba Group)

Aircraft Fuselages Are Shipped By Rail In An Unusual Combination Of Transport Modes

View this post on Instagram

A unique combination of transport modes was captured on video in a way you wouldn’t expect when Boeing 737 MAX aircraft fuselages were filmed during transport by rail through a narrow railroad tunnel. Although the video may seem to show something that can’t possibly be right, it is all too real.

The fuselages are manufactured by Spirit AeroSystems in Wichita, Kansas. Transporting such large pieces of equipment presents a challenge due to height and width limits for over-the-road transport. Due to their dimensions, they must be transported by rail without the wings attached, as the fuselages alone are too long to be transported over the road from the factory in Kansas to Boeing’s assembly facility in Washington State. The fuselages are meticulously prepped for shipment on railcars to ensure sufficient clearance through tunnels.

On June 4, 2020 Spirit AeroSystems was directed by Boeing to stop production on four 737 MAX shipsets and avoid starting production on sixteen more units for delivery in 2020 due to COVID-19’s impact on air travel in an effort to reduce unnecessary production costs. Spirit’s production was subsequently lowered from 125 units to 72 units for 2020. As of September 2020, CEO Tom Gentile said Spirit expects to be back to 10 aircraft per month on the 737 in January.

That is good news for Boeing, the passenger airline industry and the air cargo industry. Of course railroad executives will be very happy to resume shipments of this special cargo. The Boeing 737 MAX was grounded in March 2019 after two fatal crashes.

Read more about the ripple effect that the grounding of the 737 MAX created in combination with the challenges presented by the pandemic at:

Overseas Brokers Handles LaCour Trading Desk Project in Australia

LaCour has continued to expand its partnership with Overseas Brokers to handle their global transportation by sea and air, cross-border customs formalities, delivery and installation of their products, all over the world. LaCour is a major manufacturer of custom-designed trading desks, and we’ve completed projects in London, Monte Carlo, Geneva, Shanghai, Singapore, Hong Kong, Tokyo, San Juan, and Brisbane, Australia. Next up is Paris, France.

Take a look at photos from a 300 desk project we handled, on behalf of LaCour, from New Jersey to Australia, for a metals and energy trading company. The photos show the process at destination starting with grounding of ocean containers at site, installation of frames, attaching work surfaces and placement of pedestals. Through Overseas Brokers’ global network of trusted logistics partners, we are able to make this a cookie cutter process for global distribution, easily duplicated worldwide – without the need for a local dealer in every market.

The Largest Energy Project In Canadian History Requires Import Of 1 Million Tons Of Oversized Construction Equipment

Shipments of massive excavators for the $40 billion LNG Canada energy project are shipped on board roll on/roll off ships to the Port of Tacoma, Washington. The equipment is driven on and off the ships via an enormous ramp with under-deck access. After arrival in Tacoma, they are hauled to Kitimat, BC for construction of the LNG facility and a 420 mile pipeline. The removable goose-neck trailers are fitted with 7 to 9 axles because transport is restricted to 34,000 lbs per axle most of the year. In snow and freeze/thaw conditions, the trailers are upgraded to 10-12 axles to redistribute the weight of the heaviest equipment.

Read more about this project’s complex logistics at:

https://www.joc.com/breakbulk/roro-cargo/high-and-heavy-hits-road-lng-canada-project_20200824.html

(Image: Spruce Hollow Heavy Haul moves an excavator from Port of Tacoma to Kitimat, BC, on a 9-axle rig. Photo credit: Spruce Hollow Heavy Haul.)

Manufacturers Who Cut Inventories And Profit Margins To The Bone Are The Most Vulnerable To The Current Crisis

In order for western manufacturers to remain competitive, many components are sourced from China. When China delays manufacturing, western manufacturers’ ability to finish their products and deliver them to market is impeded. To compound that problem, inventories are typically stockpiled for just 15-30 days due to cost-saving inventory management methods such as “just in time delivery”. That spells double trouble for manufacturers and consumers alike.

Read more about how the current crisis is impacting global supply chains at:

https://www.theatlantic.com/ideas/archive/2020/03/supply-chains-and-coronavirus/608329/

(Photo credit: Julius Silver)

Mysterious Bullet-Shaped Aircraft Appears In The Skies Of California

An experimental aircraft, shrouded in secrecy, has been seen flying near Victorville, CA. Word is that it’s a prototype of the Otto Aviation Celera 500L which according to patents filed, would cruise around 500 mph up to 65,000 feet. The plane is purported to be 10 times more fuel efficient than other jets with similar cruise speeds and much lower operating ceilings.

Read more at:

(Photo Credit: SoCal Airshow Review)

US Manufacturer Of Trading Desks Provides Global Solution For Trading Firm In London, Singapore, Shanghai And Geneva

LaCour, a US based manufacturer of high-end, custom-designed trading desks, contracted Overseas Brokers for a series of turnkey international furniture projects. The flagship project in London entailed international shipment from the factory in NJ, customs brokerage, delivery, installation and day 2 support for 155 trading desks in London’s most iconic office building, affectionately known as the “Walkie Talkie building”. These high visibility projects were all completed on schedule for a top-tier global trading firm, on behalf of Insidesource, a leading office furniture dealer based in the US.